Micronmeter

Operation principle

Operation principle

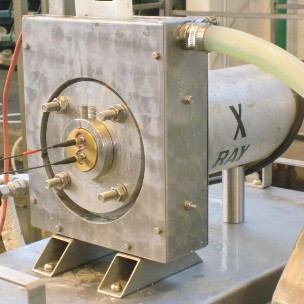

MICRONMETER is an X-Rays apparatus, it can generate alarms and other signals for the industrial process control. It measures the coating speed, in micron/ hour. It can analyze coating thickness of several materials as electroless nickel, copper, gold, silver, from 0 to 150 and up microns, with a precison of 2 % in all the range.

APPLICATION

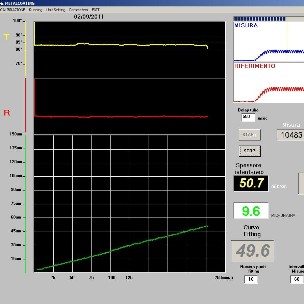

In the figure you can see, in green colour, the growing coating thickness of the process. The other data concern coating speed, average thickness, temperature etc….

In this case a PC has been connected to the system to grant the wider range of data measurements.

The system is equipped with a display that is installed on the electronic unit, in this way it can work as a stand alone unit, with no need of PC.

The calibration of the MICRONMETER is required and repeated every week, to always ensure an accurate measure within the granted range.

The operator can verify the measures connecting the electronic box to a PC with a RS485/USB cable, this remote control is possible up to 100 meters ore more.

On request, software modules can be added to generate/monitor alarms and other data and parameters.

SPECIFICATIONS

Overall dimensions (mm): (L) 720 - (W) 350 - (H) 400

Total weight (kg): 66,4