|

| |

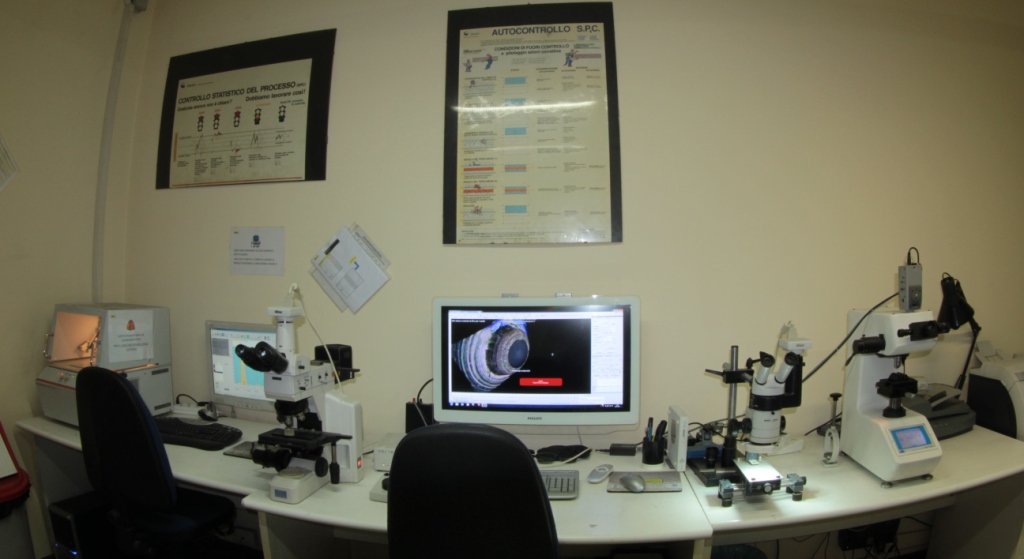

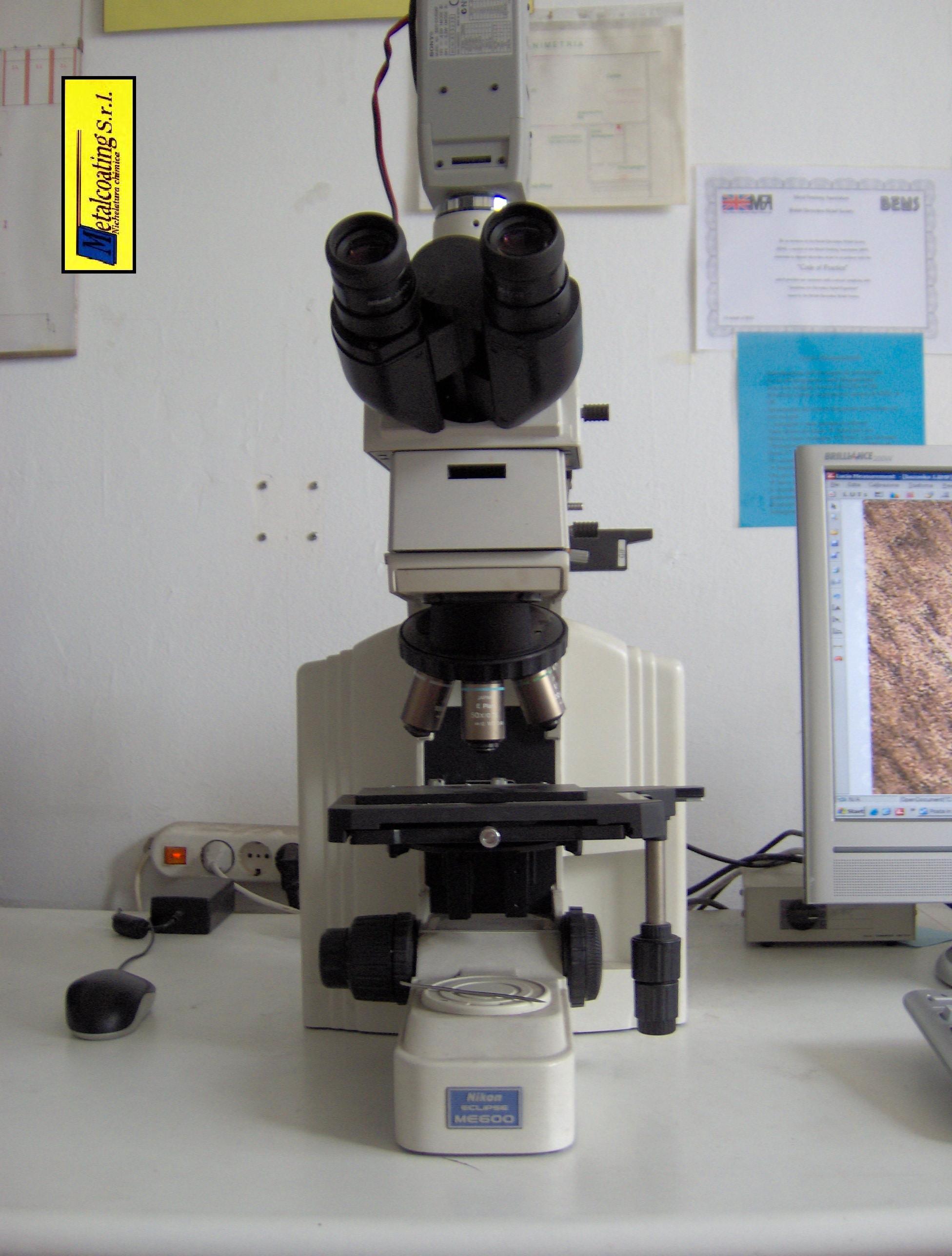

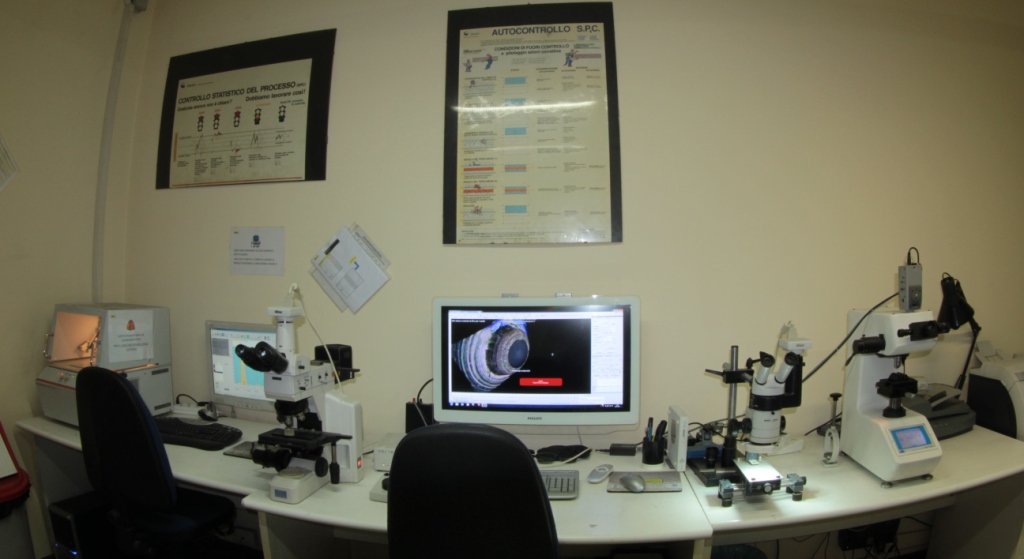

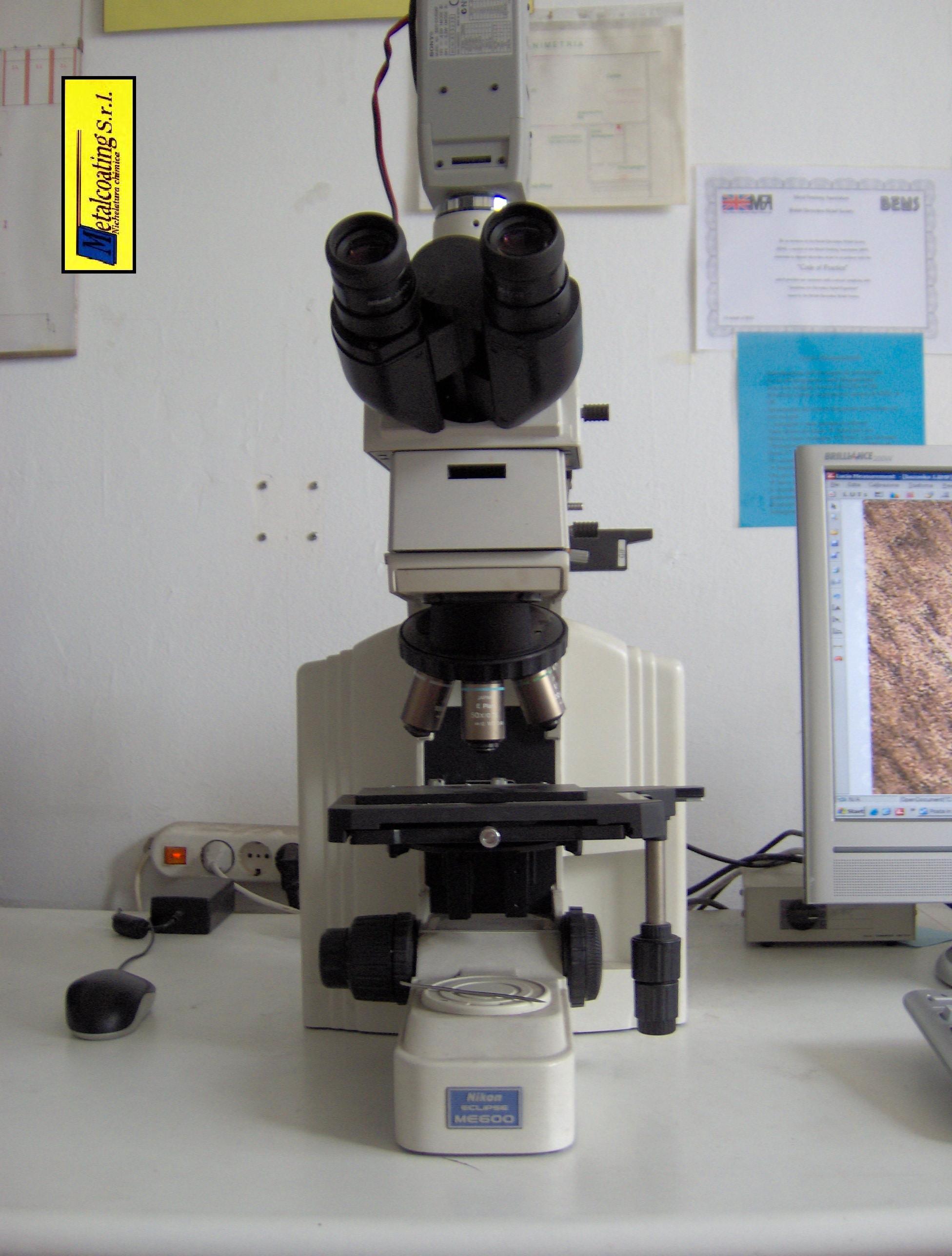

Metallographic Microscophe with camera by Nikon

Motorized Z Axis

EDF (3D surface analysis)

Magnifing: 10x 50x 100x 1000x

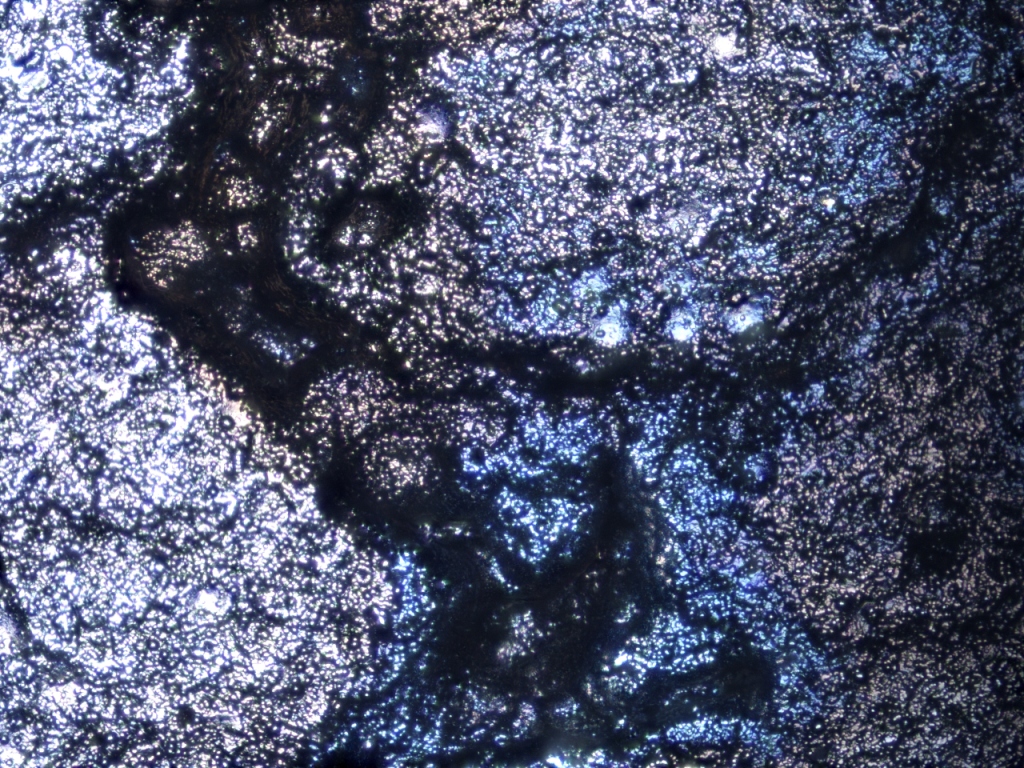

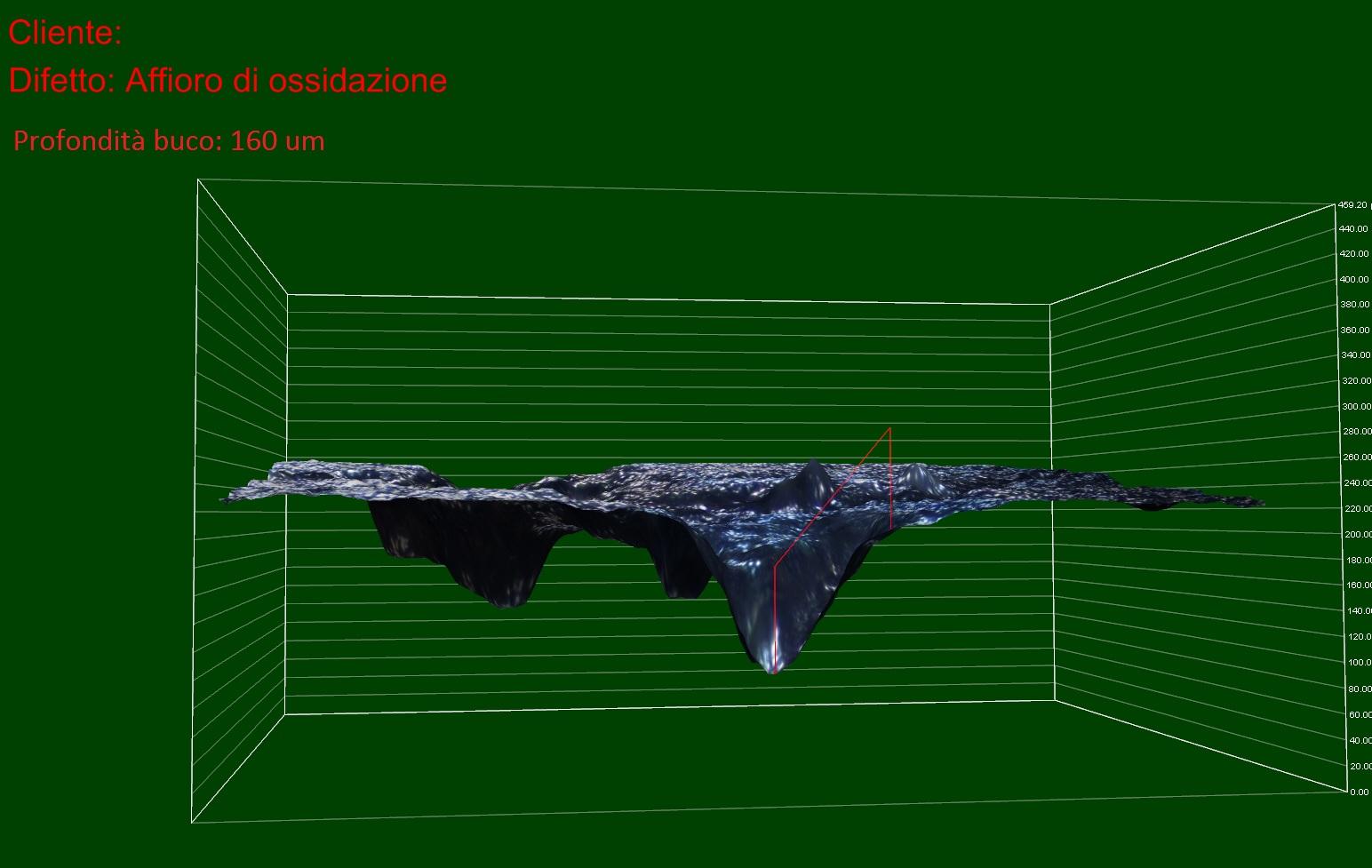

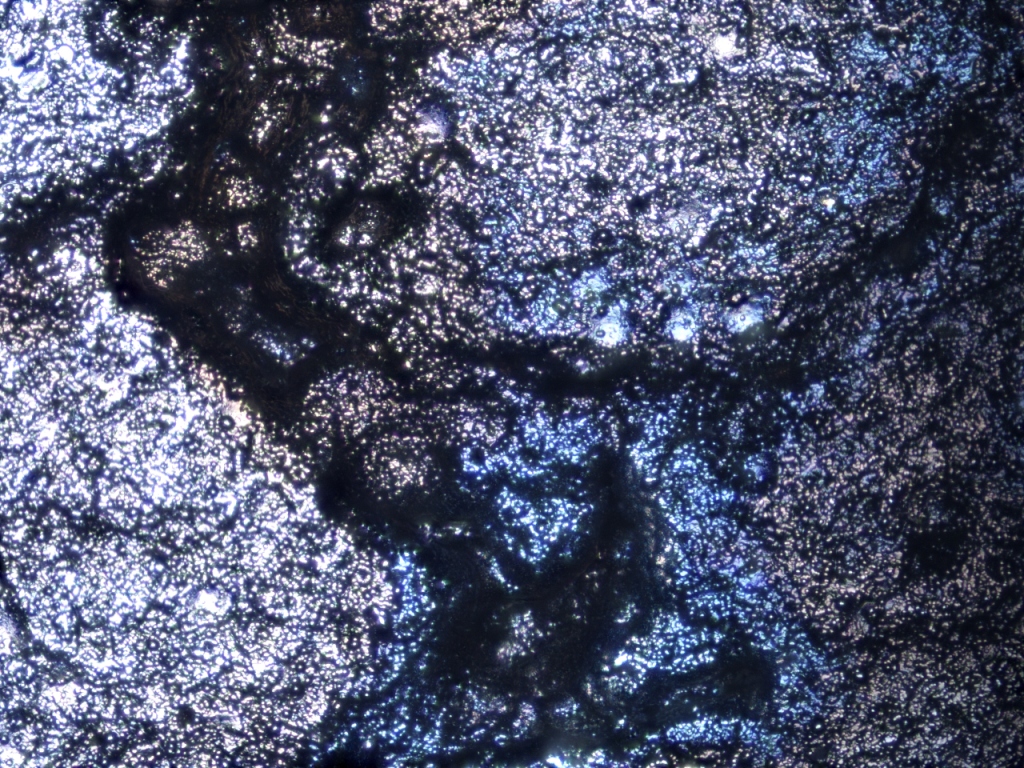

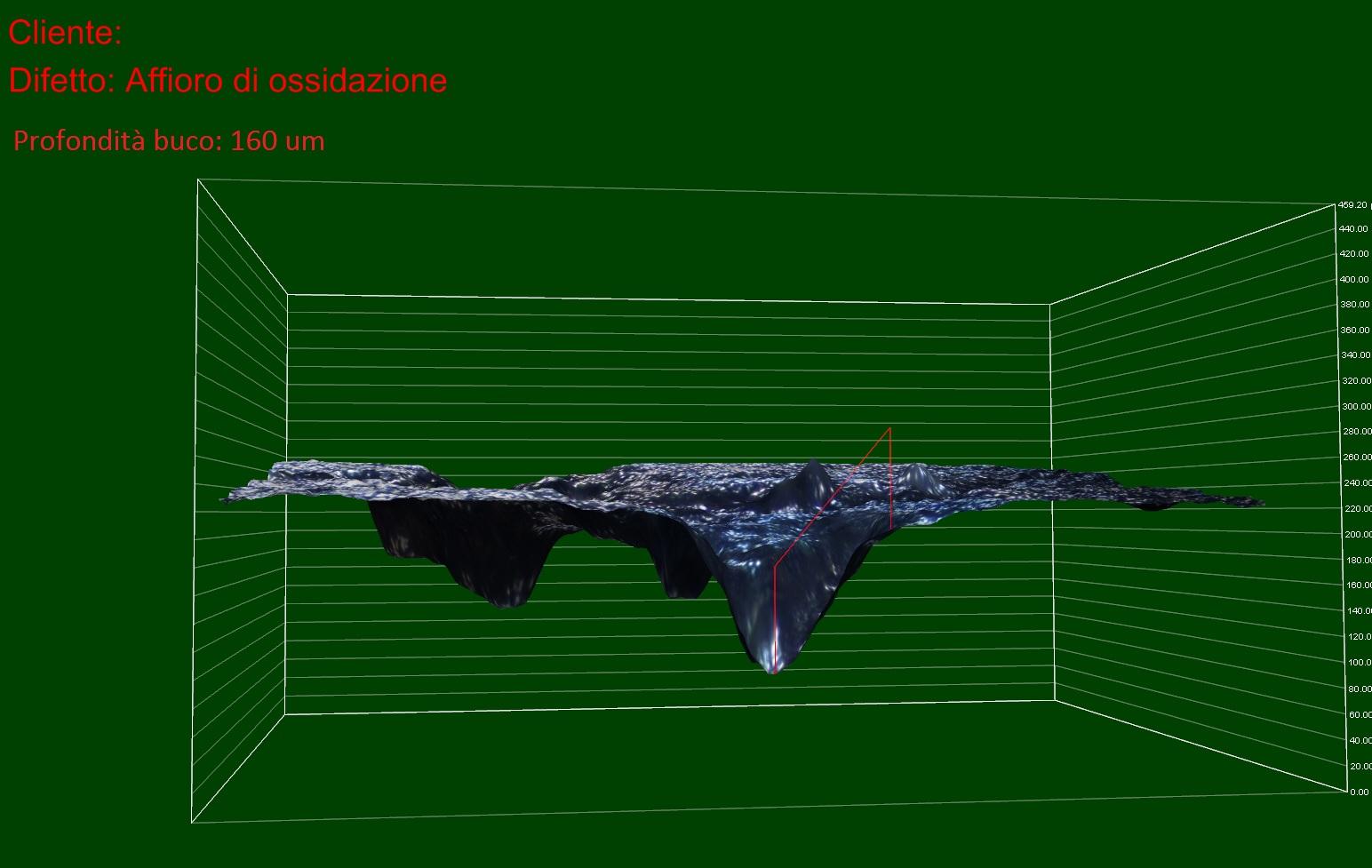

Under a little example of 3d scanning of a raw surface.

Problem: Porosity

A magnifier with camera

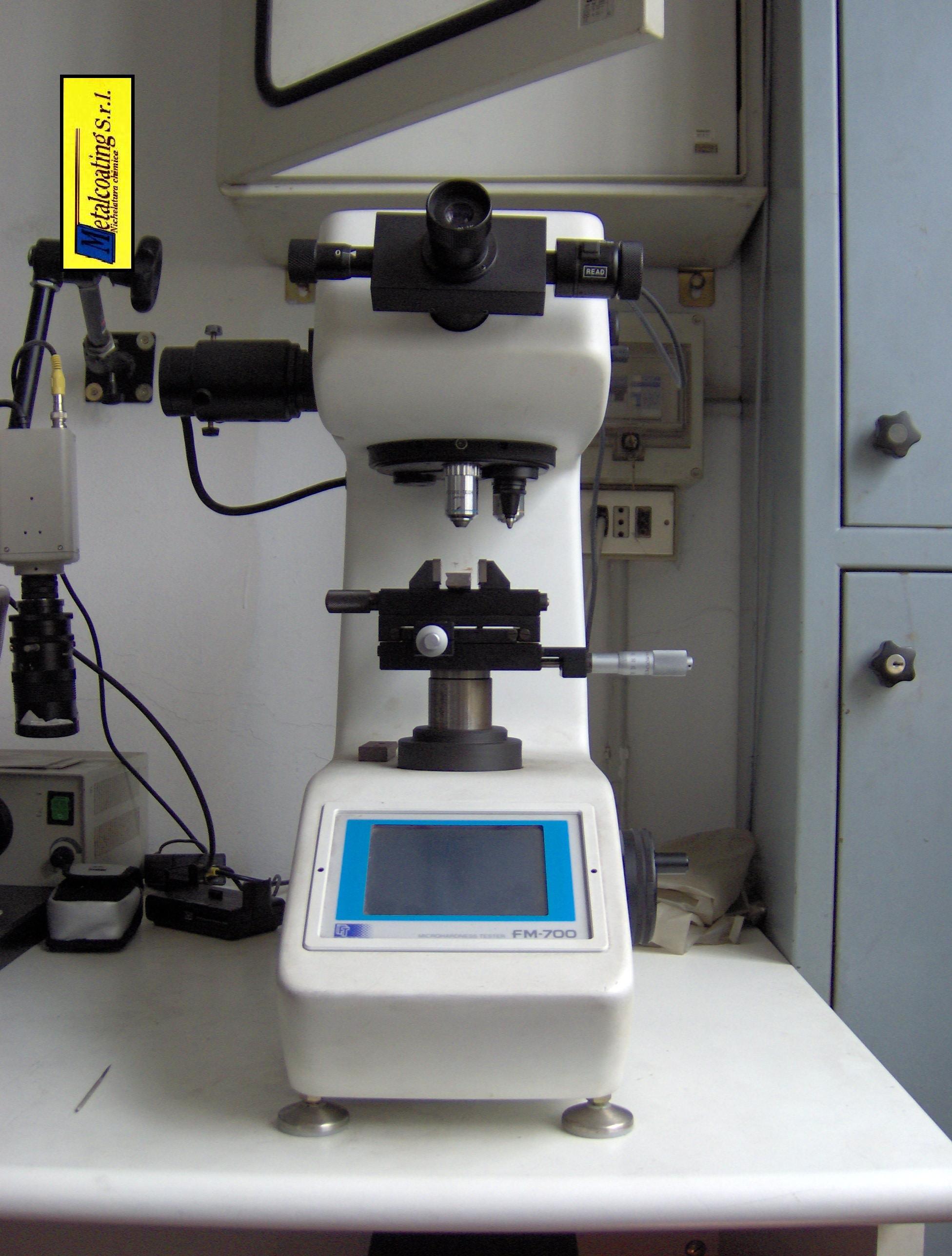

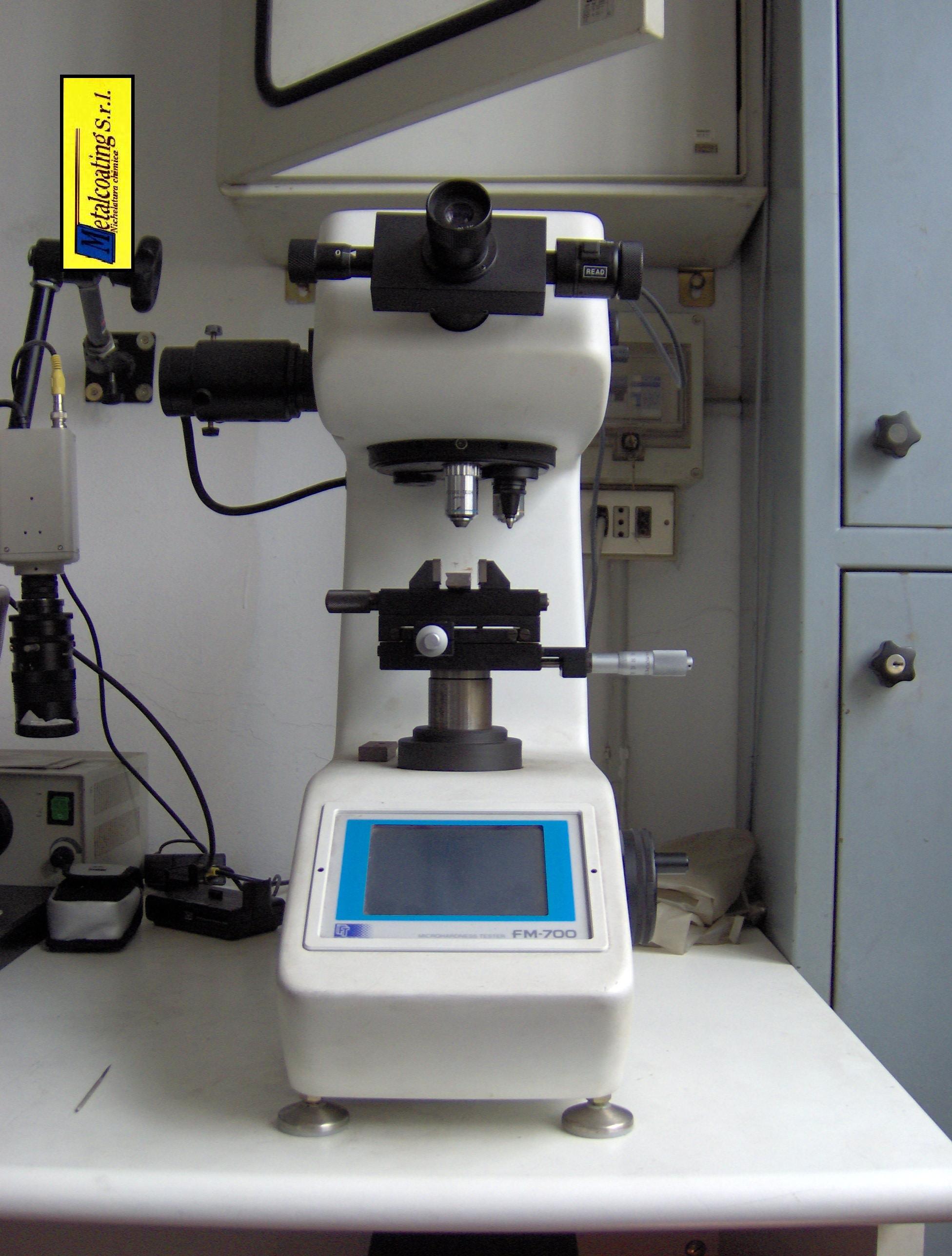

Microhardness

By means of microhardness tester Future-Tech

FM-700 one may execute measurements of hardness by means of Vickers

method: HV0,01 ÷HV1 according to PN-EN ISO 6507-1. The device is

used mostly for measurement of hardness distribution according to

any measurement track. In this manner one may determine inter alia

depth of hardened or softened layer, or by means of embedded

metallographic microscope effect measurements of hardness of

specific structural phases or segregation zones with indenter load:

98.07 ÷ 9807mN. Device facilitates photographic documentation along

with imaging of indentation. Measurement of hardness distribution

may be effected automatically or manually. Device displays result of

hardness measurement by means of Vickers method (HV) with a

possibility of recalculation into any hardness units: HB, HRC, HRA,

HRD, HK, HR15T etc. according to SEA (J-417b), ASTM E-140 and JIS.

Basic scope of the offered tests by means of microhardness testing

machine Future-Tech FM-700:

- Measurement of hardness by means of Vickers method: HV0,01

÷HV1 according to PN-EN ISO 6507-1

- Distribution of hardness as per any measurement line,

- Measurement of microhardness of specific structural phase,

- Measurement of hardened layer depth,

- Assessment of welded joint by means of measurement of

hardness on cross section

Technical parameters of micro-hardness testing

machine Future-Tech FM-700:

| Standard load |

98,07 – 9807 mN

10 – 1000 G |

| Used indenters |

diamond Vickers (HV

diamond Knoop (HK) |

| Measurement

microscope |

Magnification for measurement x400 (lens 40 x ocular 10)

max. measured length 200 µm

min. measurement unit 0.1 µm |

| Hardness value recalculation |

According to SEA (J-417b), ASTM E-140 and JIS |

| Accuracy |

According to JIS B-7734 and ASTM E-384 |

First

X-Ray instrument First

X-Ray instrument

| The FISCHERSCOPE X-RAY XUL

is a compact and universally applicable energy-dispersive X-ray

fluorescence measuring instrument. It is well suited for non-destructive

thickness measurements and material analysis.

A high count rate is achieved by using a proportional counter tube,

which allows for precise measurements. Using the Fischer fundamental

parameter method, coating systems as well as solid and liquid samples

can be analyzed standard-free. Elements in the range from chlorine (17)

to uranium (92) are detected.

The XUL has an excellent long-term stability, which among other

things is reflected in a significantly reduced calibration effort.

The instrument is well suited for measurements in quality assurance,

incoming inspection and process control.

Typical areas of application are:

• Measurements on small parts like screws, bolts and nuts

• Measurements on contacts and electronic components

• Solution analysis in the electroplating

|

Second X-Ray instrument

Coating Measurament Instrument by Oxford Instruments

|

![[Immagine logo societŕ]](_borders/Metalcoating.jpg)

First

X-Ray instrument

First

X-Ray instrument